| Choose your language |

NAVAL INTEGRALE

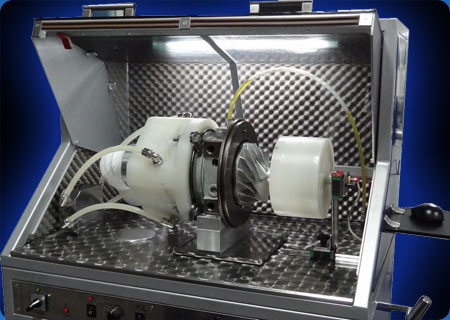

NAVAL INTEGRALE is the unique testing and balancing machine for core assembly of large turbochargers such as MITSUBISHI TD13-48Q-RCC, SCHWITZER S-4T, ABB RR151, and similar. We recommend this machine in the reconditioning procedure of small and medium marine engine turbochargers (yachts, vessels, etc.), genset turbochargers, industrial turbochargers, etc.

Core Assembly is put together from components which are previously balanced on a rotor balancing machine using TURBO REVICON® balancing method. In the above mentioned procedure, it is necessary for rotor assembly to be balanced to the tolerance level.

NAVAL INTEGRALE is the composition of the following systems:

- AIR DRIVE SYSTEM with manual command for operation speed 20.000 – 100.000 RPM

- SPECIAL FIXING TOOLS and starters of each core assembly

- VIBRATION TABLE with integrated accelerometer fixed under the table

- MAGNETIC RPM SENSOR

- OIL PUMP with heated oil tank and hydraulic installation for the lubrication of the core assembly during the test

- INDUSTRIAL PC with latest Windows operating system communicated with genuine EVB measuring electronics

- INTEGRATED PRINTER for balancing certificate printing

All above mentioned components are assembled in a beautifully designed body of the machine.

TECHNICAL PERFORMANCES

| Type | NAVAL INTEGRALE |

| Turbine types | MITSUBISHI TD13-48Q-RCC, SCHWITZER S-4T, ABB RR151, ETC. |

| Balancing speed | 20.000 – 100.000 RPM |

| Turbocharger core assembly driving device with compressor wheel cover | Special Starting Housing for each turbine type |

| Core assembly fixing tools | Special |

| Balancing method | Semiautomatic calibration Resonance Responce |

| Balancing quality (residual unbalance) |

500mgmm |

| Imbalance correction | Universal grinding tool |

| BODY DIMENSIONS | |

| Height | 1600 mm (2000 mm with PC) |

| Width | 950 mm |

| Length | 700 mm |

| Weight | 290 kg |

| AIR PARAMETERS | |

| Pressure | 8 – 10 bar |

| Connection tube | 2 x 5/4 inch / 2 m length |

| Capacity | Max. 3000 l / min |

| POWER SUPPLY | |

| Power | 2000 W |

| Voltage | 220 V / 50 Hz |

ADDITIONAL FEATURES

- Cabin ergonomically located in front of the operator

- Illuminated operating cabin with transparent rotating cover

- Maximum operator comfort is reached by ergonomic design.

- Integrated acoustic isolation

- Manual air flow control

- Multi Language Matrix system enables translating the operating software into language of choice supported by Windows 7

- Auto-saving of balancing certificates

- Extremely high precision and comfort in operation

- Attractive bi-color appearance, jewel of your workshop!